AMPERE – Additive Manufacturing based Production of Embedded Robust Electronics

Projects

AMPERE – Additive Manufacturing based Production of Embedded Robust Electronics

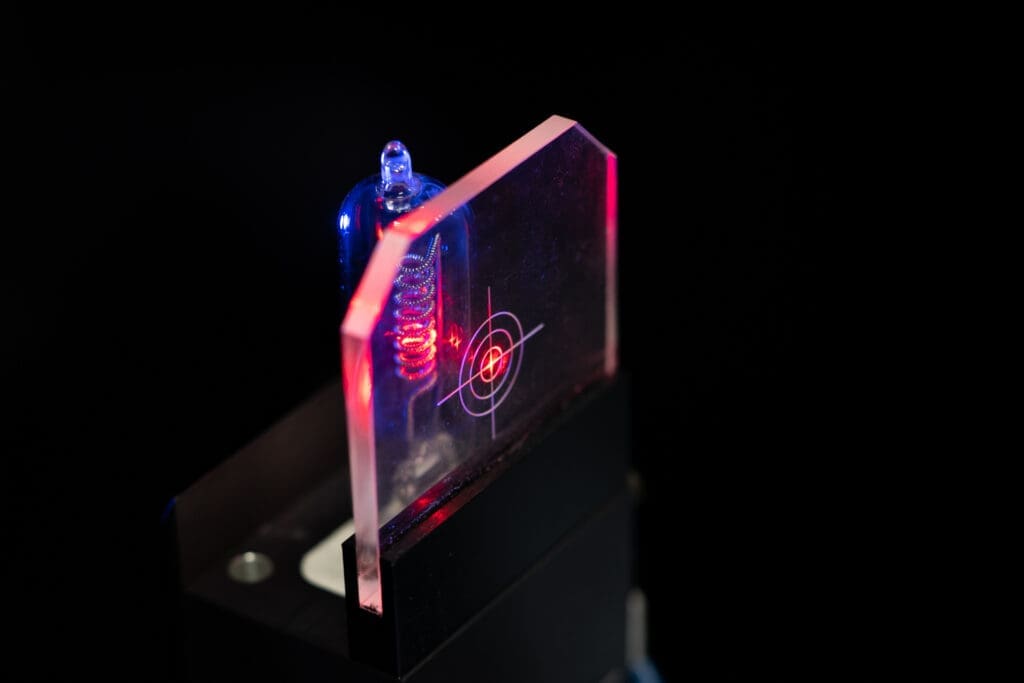

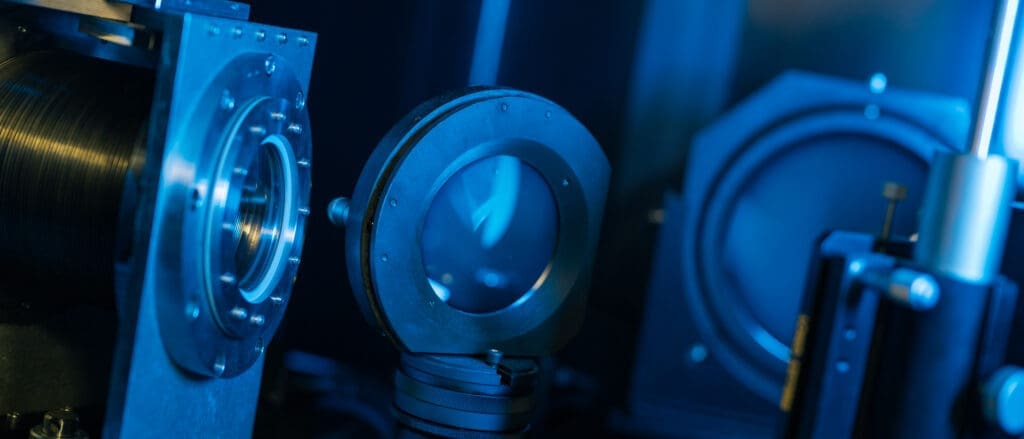

The AMPERE project will develop reliable and scalable hybrid 4D manufacturing methods for smart systems with embedded robust electronics. The new hybrid manufacturing processes of AMPERE will exploit Additive Manufacturing (AM, also referred to as 3D printing) as a core production technology that can be scaled to volume production, combined with the 4th Dimension (integration of electronic and optical functionalities). The developed process will leverage Closed Loop Controls to ensure first time right reliable production.

Four specific objectives have been set to reach the AMPERE goal:

- 1. Develop and integrate Essential Technology for scalable hybrid 4D manufacturing that is both flexible and cost effective from small series mass customisation to higher production volumes whilst meeting the real needs of industry

- 2. through digital Smart Processes of 4D products (integrated mechanical, electrical and optical functionalities)

- 3. Develop scalable and reliable Industrial Production Systems in combination with the essential technology and smart processes

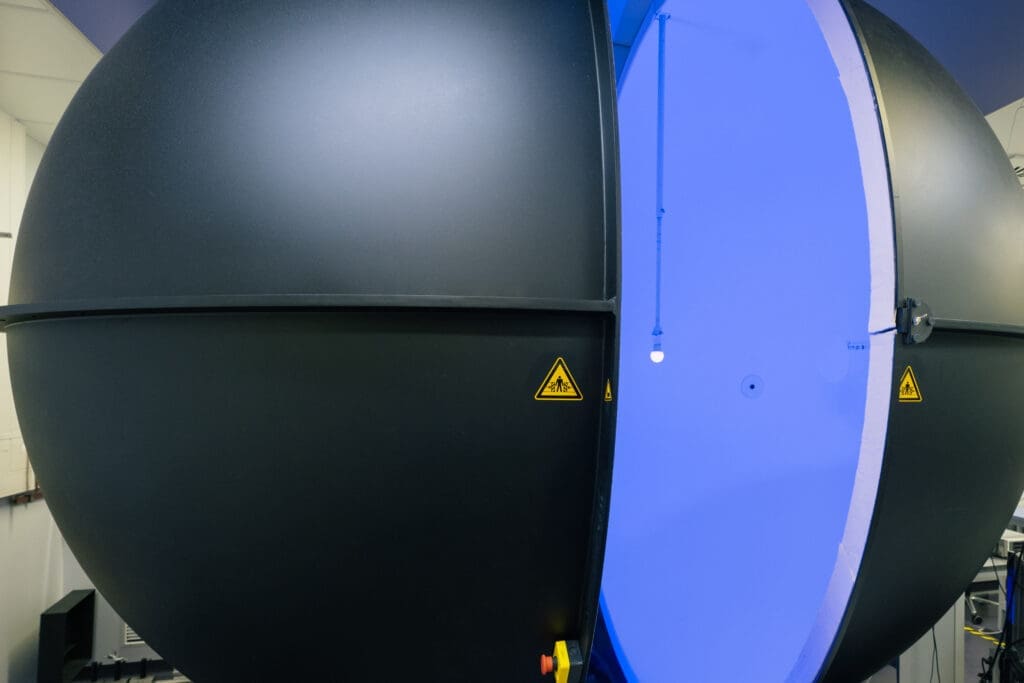

- 4. Demonstrate the hybrid 4D manufacturing approach in three innovative product cases covering different applications and sectors (LED luminaires & signal and power electronics & medical devices)

Our role

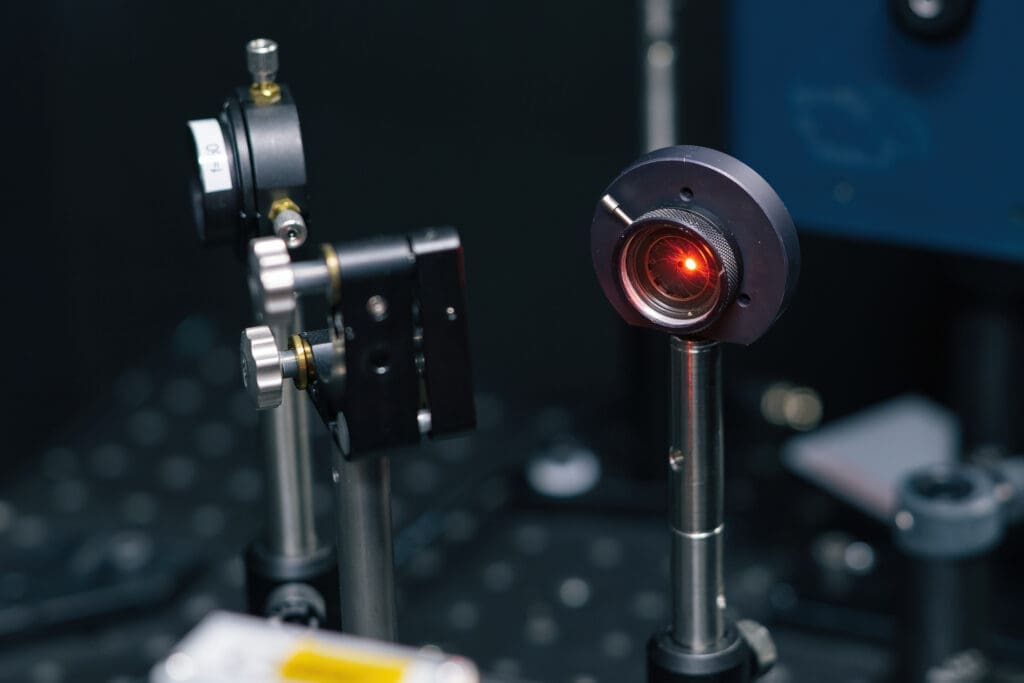

Within the project, VSL will share its in-depth knowledge and expertise relating metrology in industrial production to the partners in the project. VSL will focus on in-line and in-process metrology to enable improved process control and enhanced manufacturing performance, which follows from similar projects within this area, such as automated in-line metrology for nanoscale production (AIM4NP), or Metrology for highly parallel manufacturing (MetHPM). During the project, VSL will develop new insights relating the added value of reliable and traceable metrology for European (high-tech) manufacturing industry. In particular, the knowledge and experience from the AMPERE project will be used to aid the project partners on how to select and correctly implement metrology as they adopt the advanced manufacturing techniques from the project within their production and manufacturing process. This way, the European manufacturing industry can remain leading in this area in which metrology plays an essential role.

Start date: April 1, 2021

End date: June 31, 2024

Would you like to know more about this project?

Our experts are happy to help.

Richard Koops

Projects

Our expertise in practice

Read more about our projects